Concrete Applications using Plient fibers

Plient consists of recycled steel fibers that can replace or supplement steel rebar and mesh for applications like these

Plient Stats

Affordable:

Significant cost savings are possible.

Lower Carbon Footprint:

14x less CO2 than steel rebar. Environmental Product Declaration (EPD) for Plient fibers.

Labour:

Reduced labour because our fibers easily mix with your concrete.

Longer Lasting:

Doubles the cracking time of restrained concrete. Much tougher. Less joint damage.

Safer:

Your team does not have to handle and work with steel rebar.

Better Process Integration:

Simplified handling and dosing solution that is far simpler than bagged solutions of available manufactured fibres.

Beautiful Surface Finish:

Plient fibers are not visible on the surface of concrete floors, pavement, and pipes.

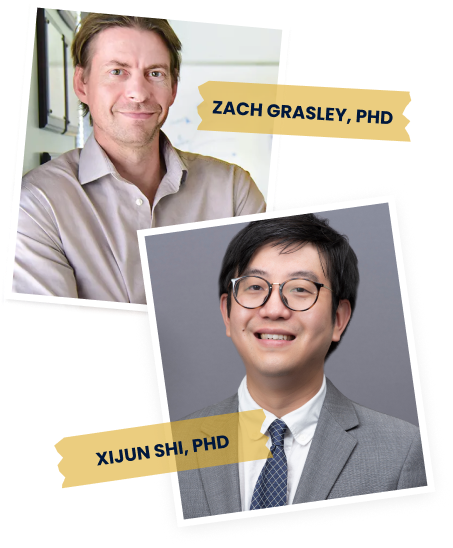

Who We are

Circle Concrete Tech

Circle Concrete Tech’s technology was developed by Zach Grasley, PhD, PE, a professor at Texas A&M University, and Xijun (Jeff) Shi, PhD, PE, an Assistant Professor at Texas State University. They have spent their careers looking for ways to make concrete healthier and better for the world.

Circle Concrete Tech was also incubated within the SuperSonic Technology incubator located in Madison, Wisconsin. Texas A&M, Texas State, Zach and Xijun have been amazing partners through this process.

Know More

Our first product, recycled steel fibers

Our first product, recycled steel fibers