Plient

Recycled SteelFibers for Concrete Applications

Patent Pending

5+ years of testing at Texas A&M and Texas State University

Circle's fiber delivery system fully integrates with your onsite operations

Concrete Applications

Using our Plient fibers, we can eliminate the need for rebar in pavement projects. We would recommend using dowel bars with our Plient fibers.

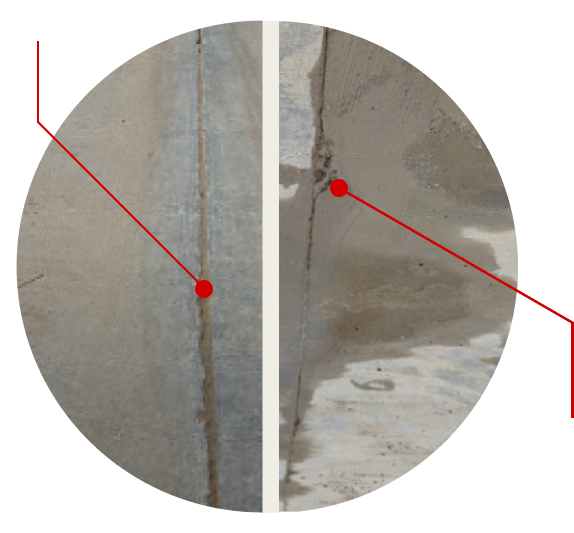

Plient joint is much more durable

Conventional joint spalled

Cost savings, 8-10%

By using Plient, your cost to pave one mile of road will drop by 8-10%.

Design Guide

We have design specs that can be followed based on your pavement project needs.

Successful Pavement Project

- A recent pilot compared conventional rebar reinforcement to Plient fiber reinforcement – same concrete, same heavy truck loading

- The conventional pavement exhibited significant joint spalling after several months

- The Plient fiber pavement showed the joint is much more durable

Using our Plient fibers, we can eliminate the need for rebar in concrete floor projects.

Co2 savings

On a 500,000sf floor, using Plient would save approximately 240 tons of CO2.

Design Guide

We have design specs that can be followed based on your pavement project requirements.

Additional Benefits of Plient Fibers for Slab on Grade

Enhanced Safety

- Less falling into grade beam trenches

- Reduced injury from workers walking/slipping on rebar mat while pouring concrete

- Less impalement or injury from cut rebar ends

- Less workers on site, fewer subs to vet

Better Anchorage

- Drilled or cast anchors will be much more resistant to damage/chipping due to tougher concrete surrounding the anchor

Less Degradation Along Joints

- The added toughness from the fibers will reduce joint degradation and longer-term maintenance

Reduced Cracking/spalling Around Column Pours

- The added toughness/crack resistance from the concrete will help reduce any damage in the floor surrounding column pours

Faster Construction

- Cutout the time spent placing/tying rebar

- Eliminate time spent fixing rebar mesh after rain, or removing rebar mesh to repair subgrade

More Secure Supply Chain

- With an offtake agreement, Circle can provide a guaranteed supply of fibers annually with lead times of less than 1 week

- Up to 35M lbs annually guaranteed

Simplified, Cheaper

- No need to scan the slab for rebar prior to coring or drilling

Using our Plient fibers, we can greatly reduce the need for rebar in concrete floor projects.

Co2 savings

One mile of concrete pipe made with Plient saves approximately ?? tons of CO2.

Design Guide

We have design specs that can be followed based on your pipe requirements.